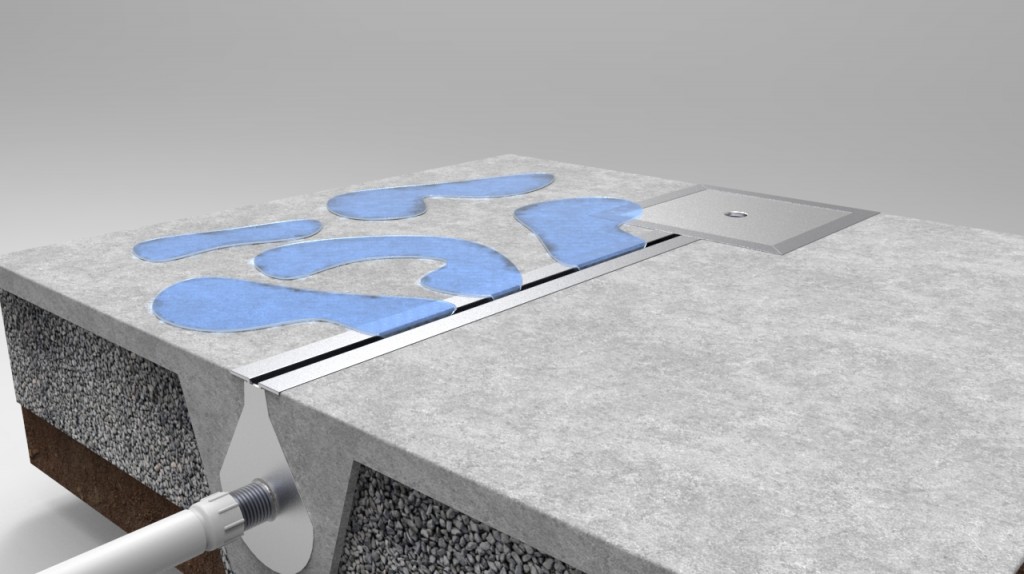

Slot Drain Detail

When Slot Drain was first introduced, grating, trench drains and four-sloped floors were standards in the drainage industry. Slot Drain changed surface drainage forever by providing the first pre-sloped, prefabricated drain system available. In doing so we provide an open floor drain system that is superior in many ways.

Slot Drain is a one-piece, built-in sloped, open floor drain / surface drain system with a linear slot on top, that is unlike anything else. The linear slot eliminates the need for grating, making it the most durable, sanitary and cost effective drainage system available. It’s applicable wherever floor or ground surfaces are subject to fluids, or have frequent cleaning requirements. Most Slot Drain applications are slab on grade, but it can also work in structural slabs and hollow core slabs. Overall, it replaces trench drains, with a self-cleaning system, at a significantly reduced cost.

Slot Drain was patented in 1988 and was the first floor drain on the market in North America to utilize the innovative prefabricated, pre-sloped and slotted concept, reducing construction labour costs. Since then, it has been installed successfully in hundreds of applications, satisfying both customers and construction professionals alike.

- It is a cost-effective substitute for corrugated steel slotted drains, precast trench drains, or cast-in-place trench drains with steel or cast iron grates. Duraslot drains use HDPE pipe, manufactured by Hancor. An outer corrugated wall provides strength and durability, while the smooth interior lining gives exceptional hydraulics. PHySical DetailS.

- This specification describes 4- through 36-inch (100 to 900 mm) ADS DURASLOT pipe for use in surface drain applications. Pipe Requirements DURASLOT pipe, as manufactured and distributed by ADS, Inc., shall have a smooth interior and annular exterior corrugations with an aluminum slot grate frame mounted longitudinally along the length of the.

Four-sloped floors, or contoured floors, are replaced with effective, low maintenance and low cost, two-sloped floors. Gone are the metal gratings and metal covers that are a nuisance to remove and clean. It’s available in both fiberglass and stainless steel, with T-Sections, 90° and 45° elbows to go around corners and other obstacles.

Find Dura Trench specification sheets and product details for your next slotted pipe project. Manufacturer of Trench drains, Slot drain, Radius trench drains, Stainless steel trench drains, and Utility trenches.

Versatile, Durable & Sanitary

A big part of what makes Slot Drain so versatile is that there is no grating. In addition to common drainage use, this makes Slot Drain especially suitable wherever grating is not desired. Some examples would be: areas subject to heavy/high traffic and food and drink processing facilities with frequent inspections/cleaning requirements. Part of what makes Slot Drain suitable for these applications is its durability and sanitary qualities.

Slot Drain is the most durable surface drain system on the market. The only parts of the drain exposed are the surface inlets which are made of stainless steel (for stainless steel drain sections) and galvanized steel (for fiberglass drain sections). The rest of the drain is embedded into the concrete, so it can handle whatever weight you want to put on it. There is no grating, which deteriorates / breaks / bends and needs replacing. This makes it especially suited for heavy/high traffic areas, such as airport, parkades, warehouses, truck and rail loading docks.

Slot Drain does not have grating to trap contaminants / bacteria, etc. A simple hose down of the floor is all that is required for cleaning. Also, Slot Drain does not absorb water/contaminants and allows contaminants to be disposed of in an environmentally manner. Another major benefit of Slot Drain is that flush valves can be added to the shallow end of the drain and set on timers or flushed manually in order to remove any sediment or contaminants automatically.

Adaptive

Slot Drain is custom made. That means we make it to suit your special requirements. Adaptations have been made to Slot Drain to accommodate things such as: depth or flow requirements, drain length and handling of process water. By modifying Slot Drain to handle process water, it saves you both time and money by eliminating extra trenching, piping and backfilling. If you have any special requirements, let us know and we’ll do what we can to accommodate you, we haven’t been stumped yet.

Slot Drain is available to be shipped worldwide and arrives fully assembled, ready to be installed. Contact us for further details on shipping, including to other countries.

Scope

This specification describes 4- through 36-inch (100 to 900 mm) ADS DURASLOT pipe for use in surface drain applications.

Pipe Requirements

DURASLOT pipe, as manufactured and distributed by ADS, Inc., shall have a smooth interior and annular exterior corrugations with an aluminum slot grate frame mounted longitudinally along the length of the pipe to accept the grate while maintaining the original pipe diameter..

- 4- through 10-inch (100 to 250mm) pipe shall meet AASHTO M252, Type S.

- 12- through 36-inch (300 to 900 mm) pipe shall meet AASHTO M294, Type S or ASTM F2306.

- Manning’s “n” value for use in design shall be 0.012.

The aluminum slot grate frame shall be manufactured from 0.063” tempered commercial aluminum meeting the requirements of ASTM B209, consisting of two parallel plates separated by spacers spanning the slot on 6” centers. The grate shall be ½ - #13 galvanized steel. The grate shall have a diamond-shaped opening and be ADA compliant. The flange at the bottom of the aluminum slot grate frame shall be riveted to the pipe with a minimum of two rivets per linear foot.

Slot Drain Threshold Detail

Fittings

Shower Slot Drain Detail

DURASLOT fittings shall be modified from fittings which conform to AASHTO M252, AASHTO M294, or ASTM F2306.

Installation

Slot Drain Installation Detail

Installation shall be in accordance with ADS recommended installation instructions. Contact your local ADS representative or visit www.ads-pipe.com for a copy of the latest installation guidelines.