How To Cut Deep Slots In Wood

- How To Cut Deep Slots In Wood Stove

- Cut Deep Slot In Wood

- How To Cut Deep Slots In Wood Lathe

- How To Cut Deep Slots In Wood Stoves

- This topic has 15 replies, 8 voices, and was last updated by .

I will need to repair the bottom of a few exterior wood door jamb. Moisture from driving rain has penetrated and caused wood rot at the bottom.

There is visible rot at the bottom four inches or so. I removed all the loose wood and cut back as high as 12” to get to solid good wood. Putting in a new prehung door is not an option right now.

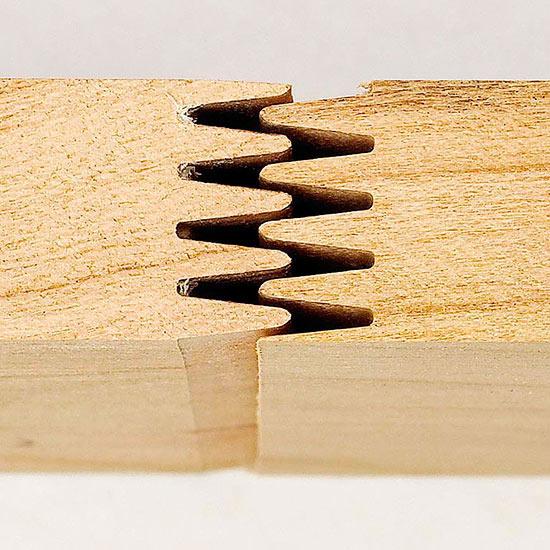

I have rebuilt the bottom 12″ of the door jamb and stop. No problem.The only issue is the original door stop has a precut slot in the door stop for kerf weatherstripping. I need to make a similar slot IN PLACE in the new door stop.

How would you make such a slot? What tool? OMT? Router? Dremel? What blade or bit?

Thank you.

Sounds like they needed a new entry door.

Dirty

A Working Pro since 1988!

Member since January 26, 2013.

How deep and wide is the required slot?

I say 1/2″ deep and the width of slot is about 3/32″, about twice the size of a OMT wood blade.

Try stacking 2 OMT blades to get the thickness or just cut the slot with one and ride the side to get the desired width.

Cut the spline off the weather strip and glue and brad nail it in place.

Dirty

A Working Pro since 1988!

Member since January 26, 2013.

kurt@welkerhomes.com wrote:How deep and wide is the required slot?

I say 1/2″ deep and the width of slot is about 3/32″, about twice the size of a OMT wood blade.

Try stacking 2 OMT blades to get the thickness or just cut the slot with one and ride the side to get the desired width.

I was actually thinking about doubling the OMT blades and see if that would work on a scrap piece of lumber. That would be an ultimate hack haha.

Does that work????

Edit: just tried…nope. That would have been nice!

I think I would use a thin kerf circular saw blade to get most of the groove, and the OMT to finish it. Might be a little wobbly, but it’ll be covered so it won’t be too obvious.

Dremel type rotary tool with router base attatchment and slot cutting bit.

Router with an edge guide.

I was thinking dremel purely for the size. Could get the slot closer to the threshold before the base bottomed out.

You mentioned it has to be cut in place, you mean that stop kurf?

Can you measure and then cut before you install, I’d do like Sorpa mentioned router and guideI’m doing the same thing now…. only I remembered the kerf in the stops.LOL

- Posts

The router will turn it to sawdust but you can buy moldings at most D.I.Y. Use a router with a cutting bit, you say you will be using an old 2 inch door, so cut a slot in each side to within an inch or so of the front of the shelf, screw the molding to the walls and slide the shelf over the moldings. All for 1 last update 2020/11/19 Departments All Departments How To Cut Deep Slots In Wood Fine Woodworking'S 19 Nov 2020 (🔴 Step-By-Step Ideas) How To Cut Deep Slots In Wood Get Free & Instant Access!!how to How To Cut Deep Slots In Wood for Auto & Tire Baby Beauty Books Cell Phones Clothing Electronics Food Food.

My Forrest Dado King Stack will cut up to 7/8' wide slot as deep as your blade diameter will allow. You want to take the time to use a router good for you but, suggesting using a track saw is a very poor suggestion for any new woodworkers to be reading on this very good site.

This article is from Issue 35 of Woodcraft Magazine.

Solid connectors that allow wood movement

Many woodworkers have learned the hard way not to glue or screw a solid wood tabletop to its base. This can be a painful lesson in wood movement because a secured tabletop that shrinks during the dry season can crack in response. On the other hand, expansion during the humid months can cause the joint to blow apart at the apron.

The solution is to use fasteners designed for the job. The three most common forms are store-bought 'figure-8' and 'Z-clips' and shop-made wooden 'buttons.' They’re all easy to install and allow the wood to expand and contract seasonally. Keep in mind that wood moves only across the grain, so mount the fasteners appropriately, as shown in Figure 1.

Figure-8 fasteners

Figure-8 or “desktop” fasteners screw to both the apron and the tabletop, and can pivot slightly to allow some wood movement. These work well for smaller tables but, due to their limited swing, I wouldn’t use them for tops wider than about 18'.

To allow tabletop-to-apron contact, drill a recess for each fastener in the top edge of the aprons on the drill press before attaching the legs (Photo A). Position the screw location about 3⁄16' in from the inside edge of the apron. Chisel the edges of the recess to allow for swing, and then install the fastener with a flathead screw (Photo B). After assembling the table base, orient the side apron fasteners at an angle before screwing them to the underside of the tabletop.

How To Cut Deep Slots In Wood Stove

Determine the necessary offset of the apron slot by measuring the clip offset and adding 1⁄32'.

A 1⁄8' slot cutter can rout clip grooves after the table base is assembled. Clamp a board to the apron to prevent router tip.

Z-clip fasteners

Z-clips are strong and offer a good choice for all sorts of tables (although they’re not very attractive). One end is screwed to the tabletop, while the other sits freely in a slot cut into the apron. To locate the apron slot, measure the offset of the clip (Photo C), and then add 1⁄32', which will ensure that the clip pulls the top tightly to the apron.

The apron can be slotted various ways. One approach is to cut a 1⁄8'-wide × 3⁄8'-deep groove on the tablesaw before attaching the table legs. Alternatively, cut the slots after assembly with a biscuit joiner set for a #20 biscuit or with a router outfitted with a 3⁄8'-deep slot-cutting bit and bearing (Photo D).

When attaching the tabletop, position the clips far enough from the side aprons to allow the appropriate amount of cross-grain wood movement. The end-apron clips should be seated fully in their slots. Attach the clips with panhead screws long enough to provide a good bite into the wood.

How much movement?

When calculating seasonal movement of a tabletop, figure roughly 3⁄16' per foot of board width. This determines how deep to place the fasteners in their side-apron grooves. For example, if you’re attaching a 24'-wide tabletop during the most humid time of the year, seat side-apron clips fully in their grooves. In the driest season, set them back 3⁄16' to allow for future expansion. For wide tabletops, use large buttons with longer tongues that slip into deeper apron grooves.

Wooden buttons

Wooden buttons are used to attach tabletops on much high-end furniture. They’re very strong and exude an aura of fine craftsmanship. You can make a bunch at one time and save some for use on future projects. Install them in the same manner as Z-clips.

Cut Deep Slot In Wood

To make buttons on a tablesaw, first mill a strip of hardwood 3⁄4 × 1 × 24' long for safe handling. Set up a dado head for a 5⁄8'-wide cut, and outfit your miter gauge with an auxiliary fence that reaches to the blade. Place a thick stopblock against the fence 1' to the side of the blade. Then clamp the stopblock to the fence a few inches in front of the blade and lock the fence.

Register the strip against the miter gauge and stopblock, to saw a dado on each end. Use a spacer to reposition the fence 15⁄8' further from the blade (Photo E), and then cut the next dado on each end. Reposition the fence and repeat the process to dado the rest of the strip (Photo F).

Bore a series of clearance holes for the screws (Photo G).

Saw each button from the strip by aligning the saw teeth with the rear of the adjacent button (Photo H). (For safety, stop the saw before moving each offcut button away from the blade.) Finish up by sanding decorative chamfers on the rear ends and sides of the buttons, as shown in the lead photo.

Cut a dado in each end of the button stock and then use a 15⁄8' spacer to reset the fence and stopblock for the next cut on each end (left). Continue in this manner to dado all the buttons (right).

How To Cut Deep Slots In Wood Lathe

How To Cut Deep Slots In Wood Stoves